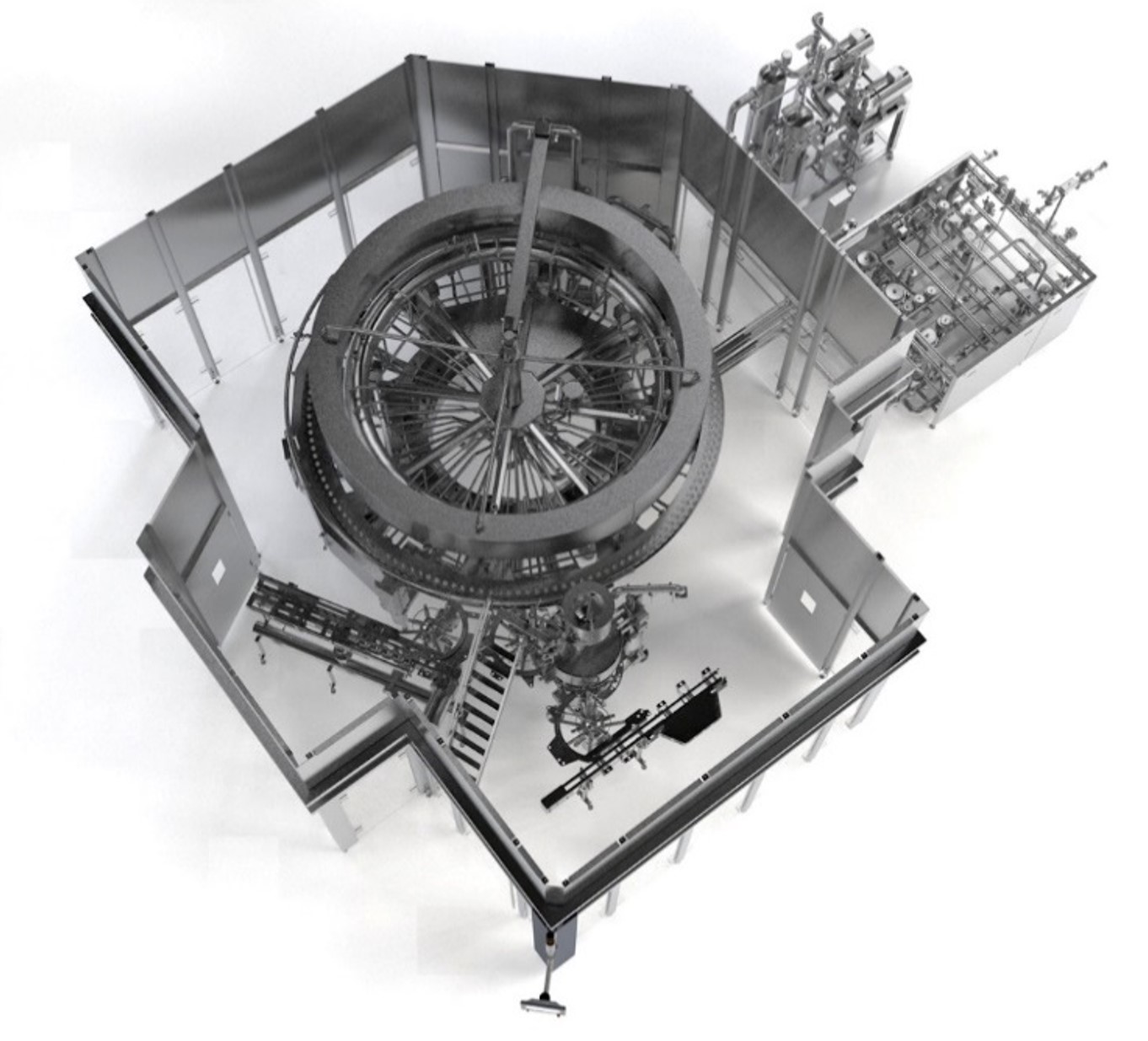

Filling of fresh milk in PET, HDPE and glass

At a glance

- Modulfill VFJ handles glass, HDPE and PET containers

- Available as

- an individual machine or in a block arrangement with a rinser or labeller

- part of the Contiform block, in a block arrangement with a blow moulder (only for PET containers)

- Output: up to 78,000 bottles per hour

- Recommended for filling milk in the cold chain with a shelf life of up to 15 days

Components

The filler

- Guarantees high microbiological safety through contactless filling

- With volumetric flow meter

- Also processes particles with a size of up to 3 x 3 x 3 millimetres

- Designed in accordance with clean room class ISO 7

Cap treatment

- Treatment of PET caps: UV light or pulsating UV light

- Sterilisation of PET caps: H2O2

- Cap flushing: O3 or ClO2 water

- Dust removal with ionised air and suction

Cleaning

- Manual or automatically positioned CIP cups

- With system for foam cleaning (in the filler)

- Available with Monotec starwheel columns or table top: fewer surfaces to clean

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events