Compact inspection system for fillers and cappers

A small inspector for big demands

Do you only have little space available? But you still want to run the full program for the fill level and cap inspection? Then the Checkmat Compact is the perfect choice for you. The compact version of the proven Krones inspector requires only a small footprint and still offers everything you expect from your inspection and monitoring system.

At a glance

- Fill level inspection unit and missing cap inspection unit

- Fill level inspection unit using high-frequency, infrared, camera, gamma or X-ray technology

- 360° cap inspection unit and tamper-evident ring inspection unit*

- Filler management

- Production management

- Quality management

- Safety management

- Automatic adjustment of the rails and the inspection unit height

* Prerequisite: Cap blower for the removal of water drips from the cap and the support ledge

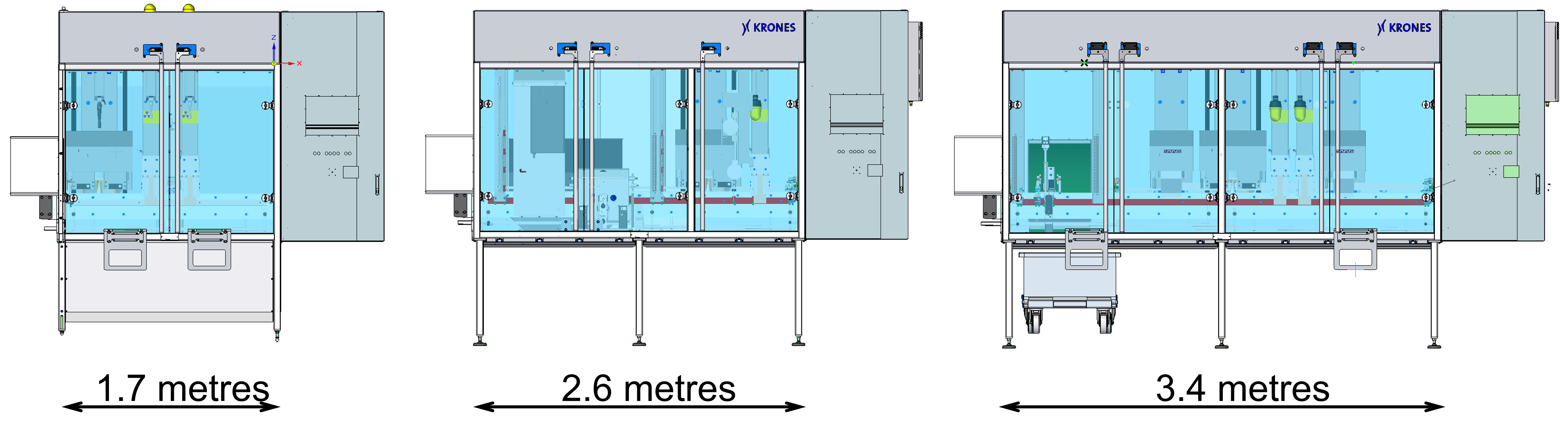

Machine sizes

Benefits to you

More safety and quality

The Checkmat Compact continuously inspects your containers – and thus ensures that only flawless products go on sale.

Increased efficiency

The inspector detects faulty materials and rejects them safely. In this way, it protects the line from malfunctions and enables a smooth production.

Low space requirements

The Checkmat Compact bears its name for a good reason: Thanks to its compact dimensions, it can also be installed on small footprints.

A lot of functions in just a small space

Even more space saved: The slim machine combines inspection units and a code/dating device system in one unit.