The flash pasteuriser for hygienic filling processes

Thermal product treatment for the best juice quality

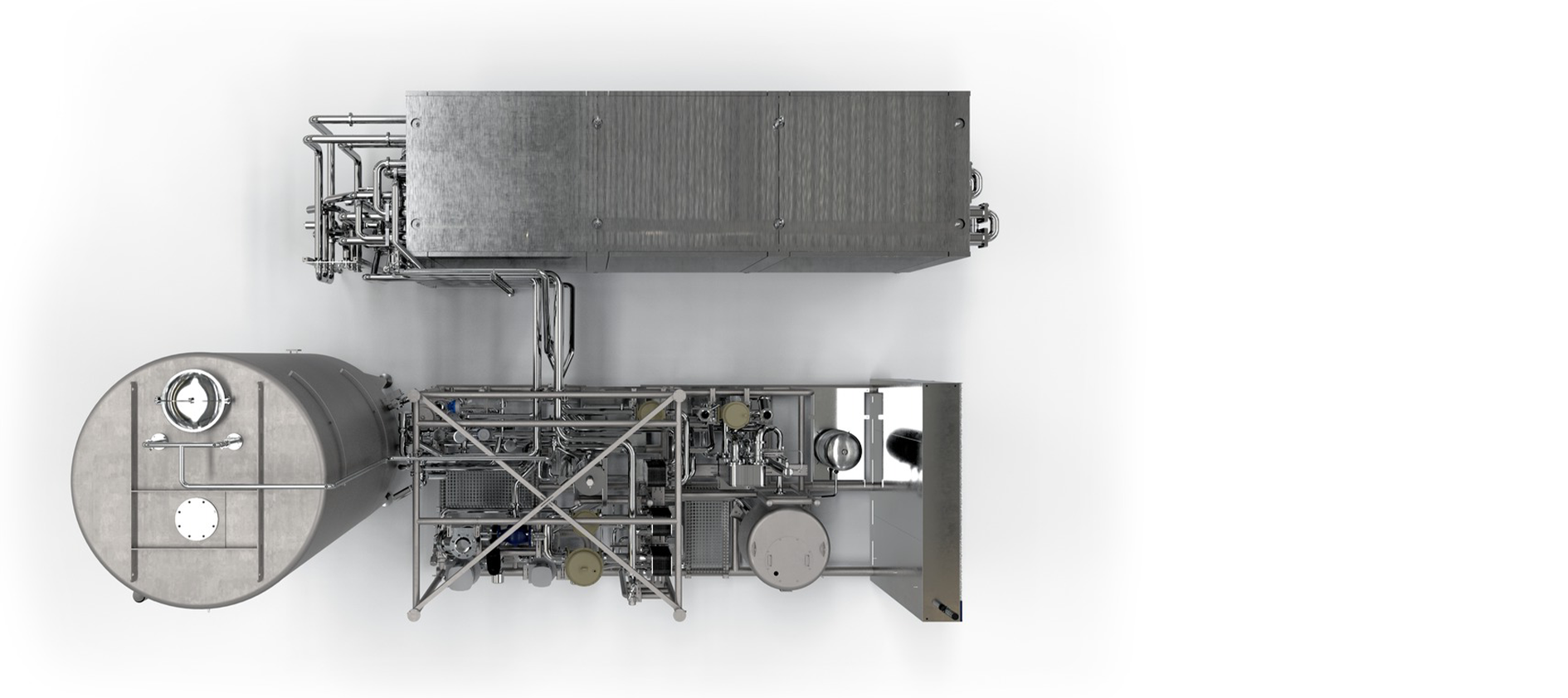

Processes for the product preservation and safe, hygienic sequences are essential factors when it comes to product manufacture – and this obviously also applies to juice. The Krones VarioFlash H flash pasteuriser guarantees the safe microbiological filling of juice. Since every product has its own requirements, Krones adjusts the machines individually to the respective applications.

At a glance:

- Output range from 7,500 to 60,000 litres per hour

- Application: Juice

Product treatment: Krones VarioFlash H hotfill heating system

Optional: Connection of

- Deaerator

- Rework tank

- Homogenizer

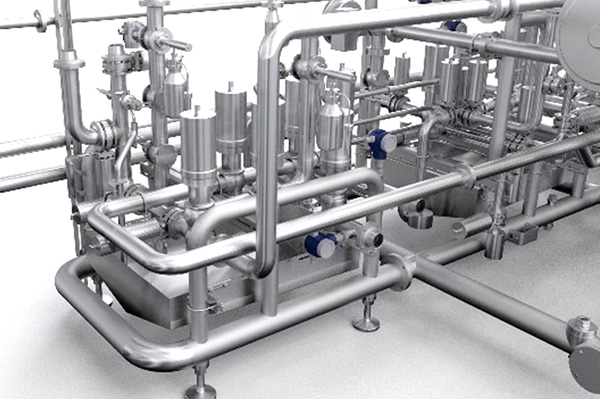

Heat exchanger and heat retention section

Gentle and safe product heating

- Designed for the characteristics of your product

- Design: Either plate heat exchanger from Krones or hygienic tubular heat exchanger built acc. to Krones specifications

- Heat retention with redundant temperature monitoring

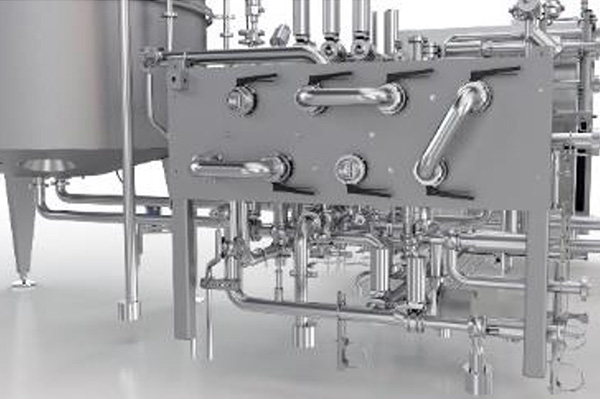

Service module

- Energy supply for product heat exchanger

- Electrical and pneumatic controller with MCC and Krones HMI

Different options for product/rework handling:

In the standard version, the heating system is designed with a supply tank for disconnecting the upstream process. An optional rework tank can be connected to pump the mixing phases.

In the picture:

- Enlarged supply tank that can be used as a rework tank at the same time

- The content of the rework tank can be mixed from 5 to 100 percent with the freshly fed product

Design features

Integration according to your needs

- Direct connection or via swing bend panel or valve manifold

High product quality also under difficult conditions

- Particle filters in the media supply pipe (during heating and cooling)

- Steam reduction compensates pressure fluctuations

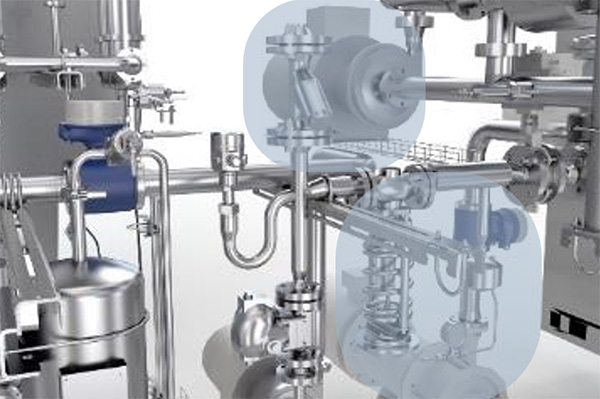

Intelligent design for easy maintenance

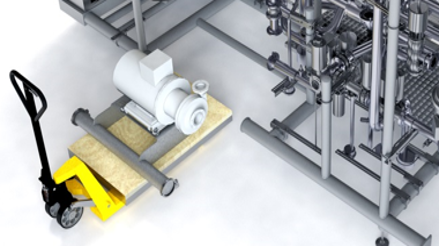

- Easy access to the pumps

- Ways for maintenance

Stable pasteurisation conditions

- Separate water tank to control the water circuit separately from the infeed tank

- High accuracy for the temperature control

The efficient product deaerator VarioSpin

You have invested a great deal in order to develop a fruit juice beverage of top quality? You want to be sure that this quality is preserved in the manufacturing and filling processes? Then integrate the Krones product deaerator VarioSpin in your manufacturing process. With VarioSpin you make use of a compact vacuum-assisted deaerator which permits highly effective filling processes without the formation of foam at the filling valve.

Standard: Heat recovery within VarioFlash H

Recovery I

In the hotfill process, the VarioFlash H is designed with an excess output of approximately five to ten percent compared to the filler. This excess output leads to permanent circulation throughout the entire system in order to compensate for heat losses at the filler or in the piping system.

Before the product is returned to the supply tank, it is cooled down accordingly. Via an internal water circuit, this energy can then be used to regeneratively heat cold product.

Recovery II

If the temperature required for heating is higher than the filling temperature, an internal energy circuit is used to recover the excess energy. Through this heat exchange, the filling temperature is precisely set.

Separate treatment of juice and fruit pieces FlexiFruit

The quality of juice is not only defined by its taste but also by the feeling in the mouth. The Krones dosing systems are the solution for all bottling plants that strive for top product quality and wish to lean on a high-standard fruit juice production as compared to the conventional hot filling process. Krones FlexiFruit is an intelligent and self-adjusting pre-dosing system which controls the dosing quantity on its own via the Modulfill filler.

Benefits to you

High accuracy and product safety

The highly accurate temperature control ensures guaranteed microbiological quality. The exact adherence of the selected heating temperature is redundantly monitored.

Across-the-line energy concept

By coupling the VarioFlash and the LinaCool tunnel cooler, energy synergies can be utilised across the entire line. You thus benefit from optimally utilised energy resources and ensure more sustainability in the production process.

Flexibility in the production process

Product changes can be realised within just 30 minutes (between the last and the first bottle) with intermediate water rinsing and appropriate hardware and software.

Hygienic design

The compact and hygienic design ensures high process safety, eases maintenance and reduces the loss of product through reduced mixing phases during the start and stop phases.

Precise tracking of all operation steps

All process-relevant parameters are saved and archived by an electronic data writer.

References

The VarioFlash is a model for success. With more than 250 reference customers*, this machine is one of our most-built units guaranteeing best product quality worldwide.

* Version 2022