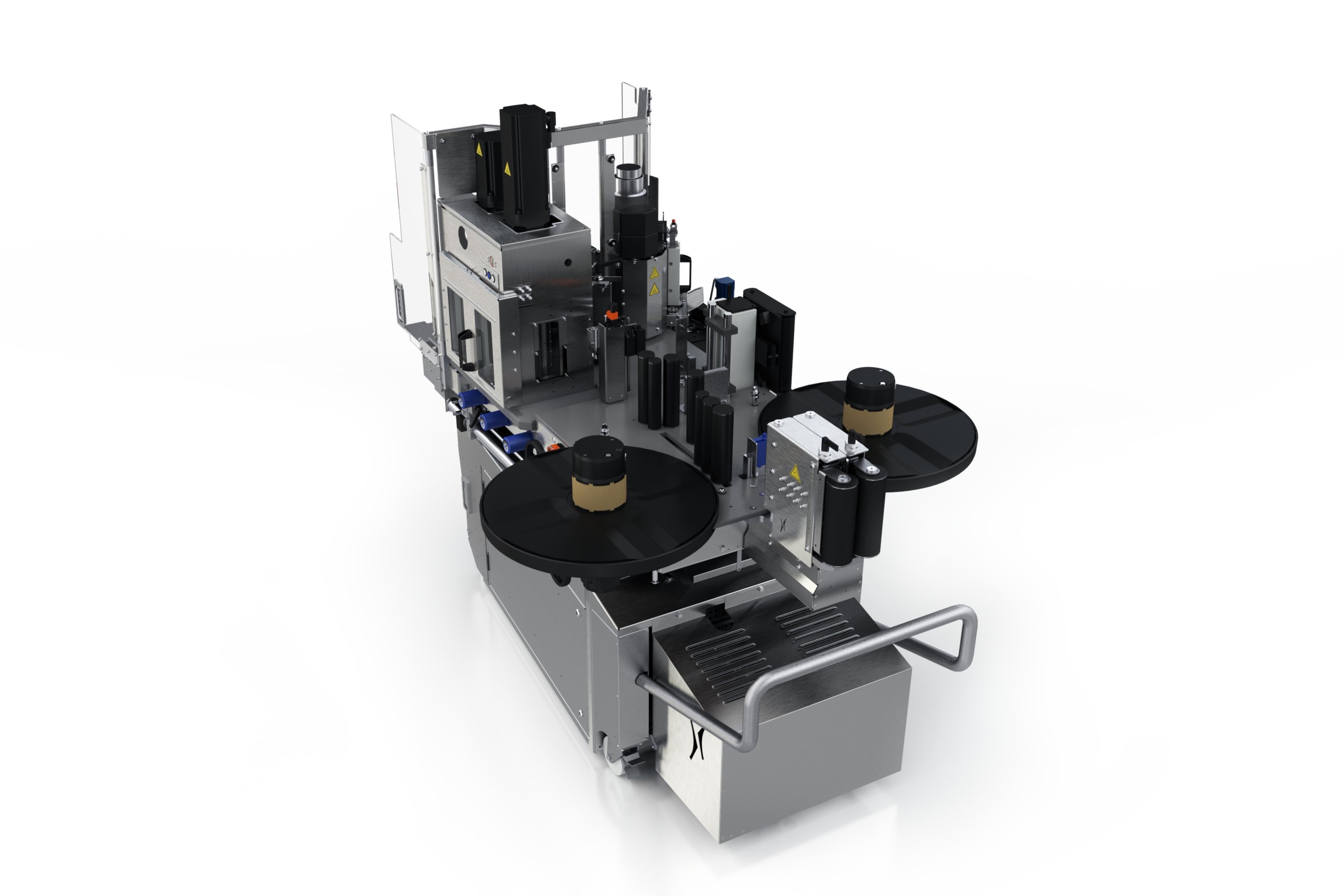

Ready for anything: the ergonomic labelling machine with interchangeable labelling stations

The all-round labeller

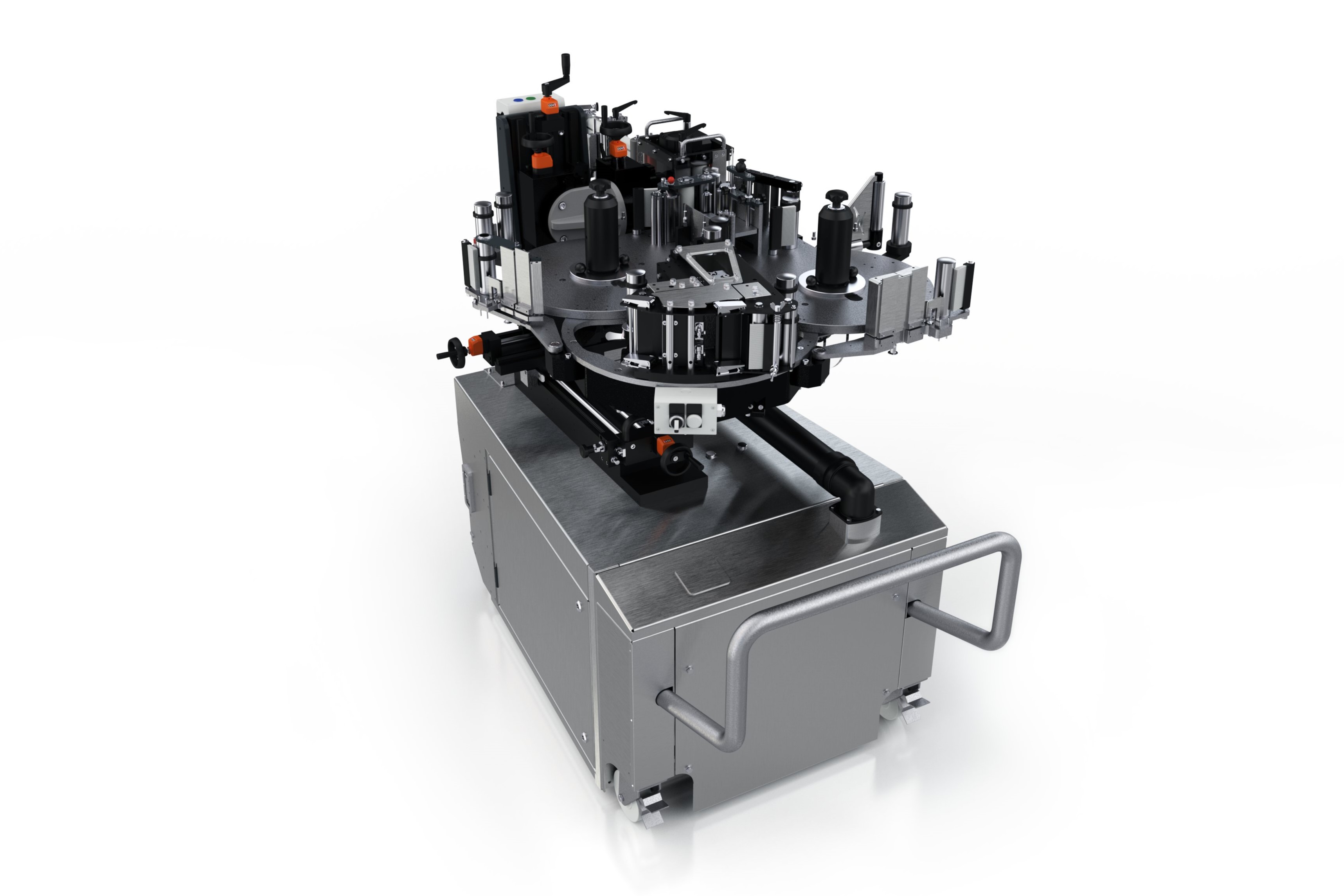

The EM series from the Krones labelling systems offers the perfect machine for every application. It offers three main machines, six table diameters, seven labelling station types – and it offers numerous options for combining the individual elements with each other. The Ergomodul is its technological spearhead: A lean, highly efficient machine for ultra-flexible applications.

At a glance

- High-tech model of the Krones EM-series

- Columnlessmachine with exchangeable labelling stations

- Labelling method and speed:

- Pre-cut labels with cold glue up to 72,000 containers per hour

- Pre-cut labels with hotmelt up to 72,000 containers per hour

- Reel-fed labels with hotmelt up to 100,000 containers per hour

- Self-adhesive reel-fed labels up to 60,000 containers per hour

EM = Ergonomic Model

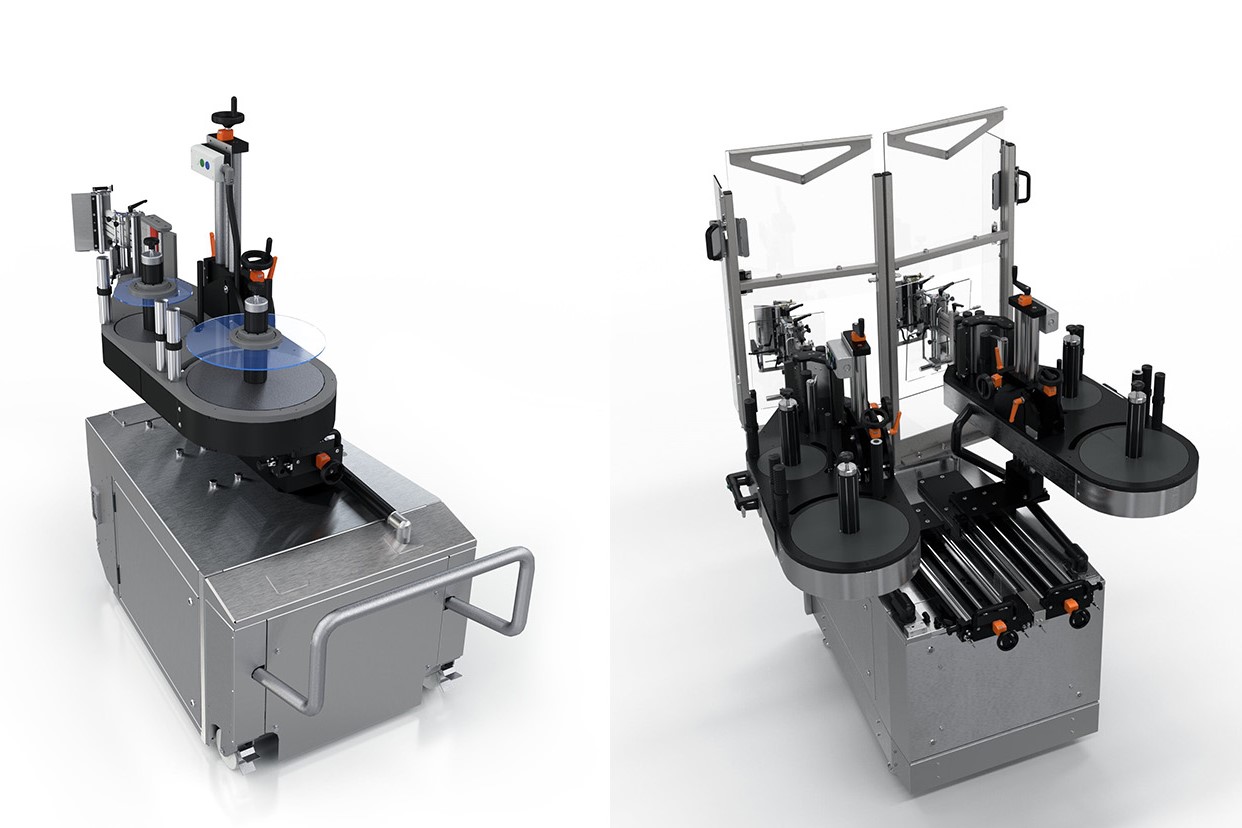

The EM-series: All models at a glance

|

|

|

|

|

|

Pre-cut label application with cold glue |

Reel-fed labelling with hotmelt |

Pre-cut label application with hotmelt |

Reel-fed labelling with self-adhesive labels |

|

|---|---|---|---|---|

|

Machine with table top |

Ergomatic | Contiroll | Canmatic | Autocol |

|

Columnless machine with fixed labelling stations |

Ergomatic Pro |

_ |

_ |

Autocol Pro |

|

Columnless machine with interchangeable labelling stations |

Ergomodul | |||

Technical features

| Features | Advantage | |

|---|---|---|

|

Material |

|

|

|

Dimensions |

|

|

|

Servo drives use throughout all applications |

|

|

|

Machine design |

|

Reducer complexity as a red thread:

|

|

Touch-screen |

|

|

|

Bottle plate control |

|

|

|

Labelling stations |

|

|

Labelling stations: All models at a glance

Labelling station for pre-cut labels with cold glue

Technical features and benefits

- Hygienic design

- Optimal cleaning properties

- Polygon holders for glue roller, pallets and gripper cylinders

- High-precision labelling

- All parameters saved in the operator program

- Exactly reproducible settings

Options

- Stainless steel labelling housing

- Automatic magazine loading system

Labelling stations for reel-fed labelling with hotmelt – high output range

Technical features and benefits

- Hygienic design

- Optimal cleaning properties

- Light-weight vacuum-grip cylinder

- Optimum accessibility

- Reduced change-over time by up to 20 percent

- Newly developed gluing unit

- Absolute control over the glue application

- Reduced heat-up phase by up to 20 percent

- Reduced energy consumption by up to 15 percent

- Automatic reel splicing unit

- Electronic cutting unit

- Guaranteed cutter replacement not required earlier than after 120 million cuts

- Necessary time for cutter replacement: 1 minute – without service personnel

- Overlap correction possible during production

Options

- Unit for the detection of splicing points

- Antistatic equipment

- Label extractio

- Glue fume extraction system

Labelling station for pre-cut labels with hotmelt

Technical features and benefits

- Overlap correction possible during production

- Robust technology for leading-edge gluing and trailing-edge gluing

- Output: up to 72,000 containers per hour

Option

- Hotmelt spraying system

- Contact-free glue application

- Closed glue system

- Glue consumption reduced by 50 percent

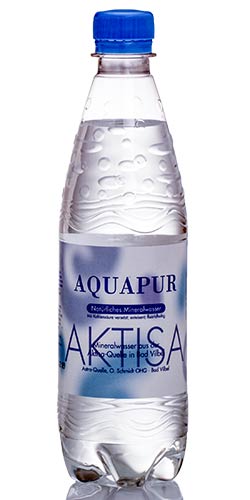

Labelling stations for self-adhesive labelling – low and medium output range

Technical features and benefits

- Outputs of up to 60 meters per minute

- Operation without any pneumatic components

- Reduced consumption costs

- Ultrasonic sensor independent from the materials

- Precise label position

- Four-axes adjustment

- Adjustment indicators for all installation possibilities

- Simple film guidance and driven roller

- Hybrid roller technology for supplying the label film

- Flexible applications for thick, thin and multi-layered labels

- Compact design

- Top accessibility

- Ideally suited as an additional labelling station

Option

- AUTO-change: DUAL variant with both applicators on one modular labelling station

Labelling stations for self-adhesive labelling – high output range

Technical features and benefits

- Outputs of up to 200 meters per minute

- Ultrasonic sensor independent from the materials

- präzise Etikettenposition

- Four-axes adjustment

- Adjustment indicators for all installation possibilities

- All parameters integrated in the central operator touch-screen program

- Easy reproducibility of the adjustments

- Feed and tension roller technology with contact-free label buffer system

- Highest precisions at the application wedge

- Processing of even ultra-thin labels

- Two reel holders

- Best operating comfort

Options

- Automatic splicing

- Five/six-axis adjustment

- Separately driven rewinder

Benefits to you

Custom-fit technology

The Ergomodul can be equipped with various labelling techniques, labelling station types and optional packages. Simply pick your suitable elements and create your individual machine.

Technology from a single source

Everything fits together here: Right from the start, the complete EM series was designed as a homogeneous product series. Disregarding of how you will configure your machine – the individual components will always seamlessly fit into each other and push each other to the highest performance.

Efficiency as a red thread

How can you perform a lot with little input? The new Krones labellers will show you exactly how that works. Regardless of whether talking about the spare parts management, the footprint, the operator effort or the energy consumption: This complex series has been designed for the maximum efficiency up to the smallest detail.

Investment for the future

The EM series comprises all the know-how of more than 70 years of Krones development. The result? An advanced machine series which particularly provides you with the following: the certainty to be equipped for any challenge of the future.

This is why the Ergomodulis enviro-classified:

- Use of servo motors of the efficiency class IE4 or similar

- No drive train lubrication required

- Always use of food-grade lubricants

- Media measuring package and optional energy measuring package

- Significantly reduced noise level

- Safety standards according to the Machinery Directive 2006/42 EG

- Consideration of the 2006/95/EG and EU-EMV Directives (2004/108/EG)

- Design according to::

- EN ISO 12100

- EN ISO 13849-1

- EN 60204-1

- EN 61000-6-2

- EN 61000-6-4

- EN 13849

- EN 62061