Leakage detection for beverage cans

Scanning without contact

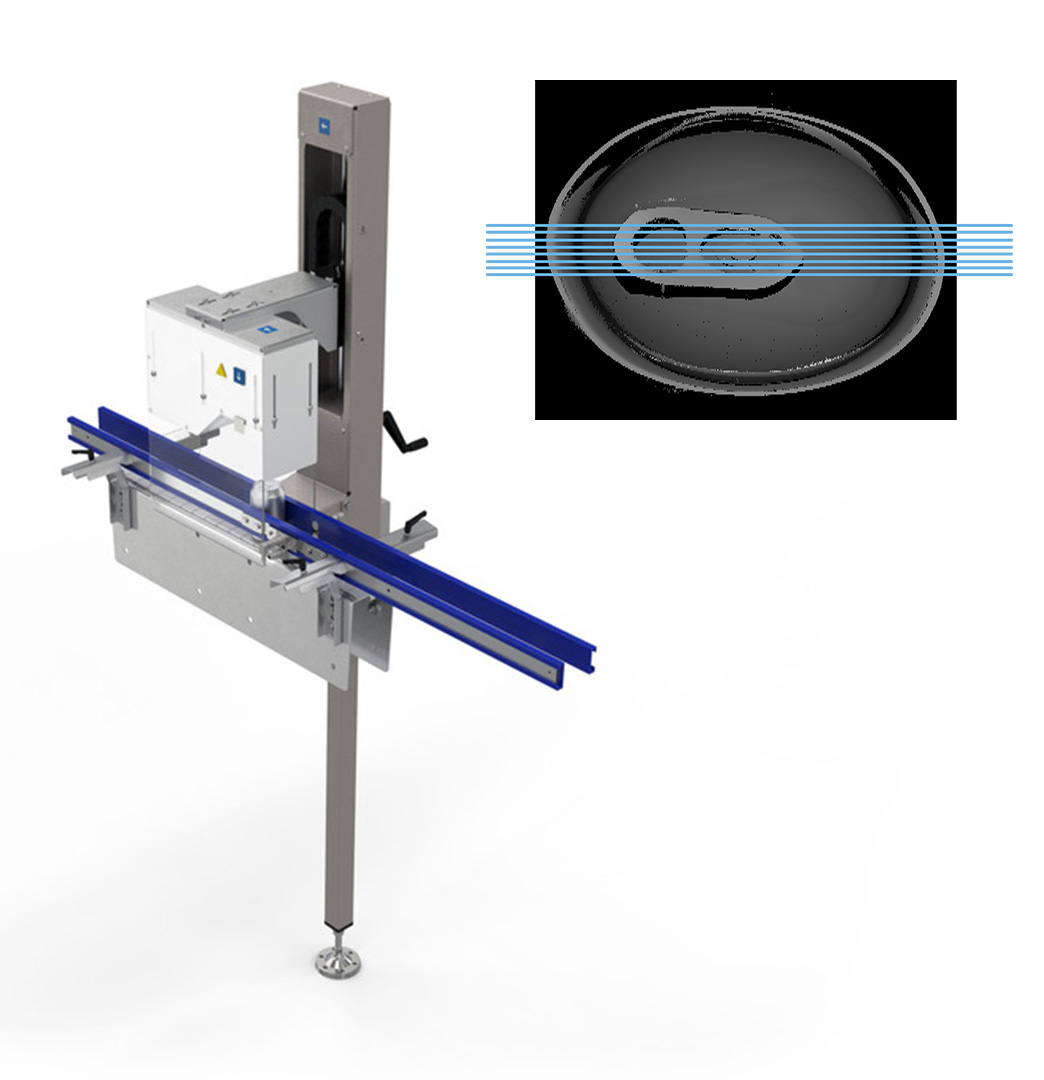

Leakproof or not? The Checkmat SLD can quickly and easily detect it – without touching the can. This is realised with a clever process that measures the bulge of the lid and thus determines the internal pressure.

At a glance

- Leakage detection for cans

- Contact-free process with 3D scanner and camera

Method of operation and benefits

Leakage detection system (SLD = Seam Leakage Detection)

A fanned-out laser beam is focused on the object to be measured and analysed with a camera. The laser generates a 3D profile. The lid bulge is used to indirectly determine the internal can pressure - and thus its leak tightness. Containers with too little bulge are rejected.

Advantages

- Contact-free, no wear

- No speed restrictions

Requirement: Corresponding layout drawing of the filling line. Internal pressure is usually built up approximately 30 minutes after filling.

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events