Quality control for beverage cans

Twice as safe and thrice as quick

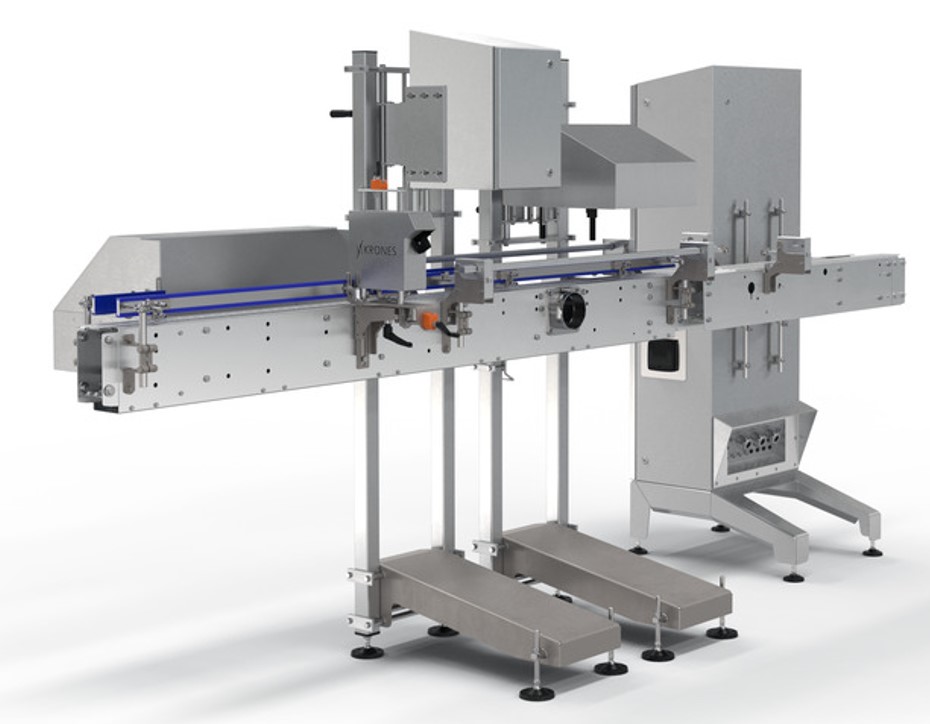

If you see 33 cans whizzing past you every second, you can lose track of what's going on. This does not apply to the Cantronic. The can inspector detects even the most minute dirt or deformation at this speed. Both the cans and the machine benefit from such thoroughness: The cans, because they reach the point of sale at their best possible quality, and the machines because there are no malfunctions caused by faulty cans.

At a glance

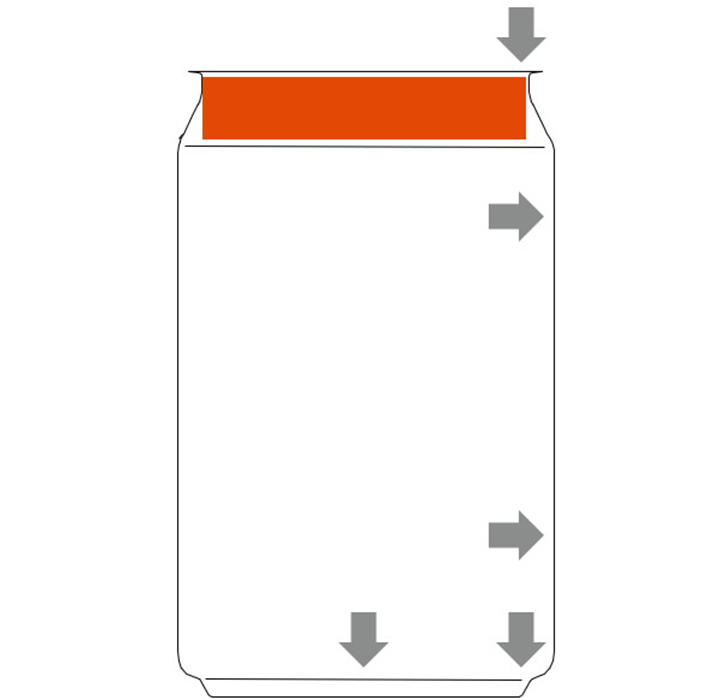

- Quality control of cans

- Flange

- Inner side wall

- Base

- Optional additional equipment:

- Test container program

- Inner side-wall inspection unit with additional camera unit

- Rated output: up to 130,000 cans per hour

- Increase of the line efficiency

Structure

Faulty test containers are used to check the inspection units for

proper operation.

Technology used

- Multifunctional test container with colour strips, for example:

- Test container 1: Base centre, inner side-wall bottom, beading

- Test container 2: Base border, inner side-wall bottom, beading

Method of operation

- The program is called up automatically after a specified number of

containers or time - Results display after successful/unsuccessful through passage

- All of the results are saved automatically with the date and time

Benefits to you

- Very high product safety

- Simple and low-cost manufacture of the test cans

Benefits to you

Precise quality control

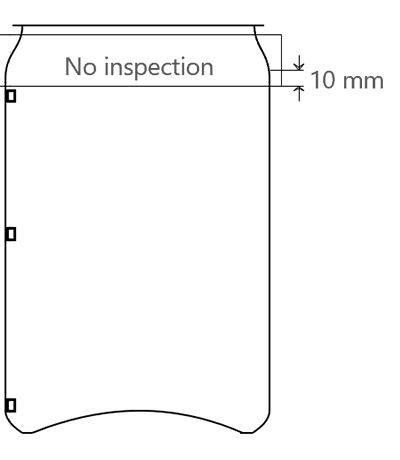

The high-resolution basic camera detects even the most minute dirt and irregularities. The additional camera unit enables you to even detect creases and dirt in the neck area which are very hard to find.

High line efficiency

Damaged or deformed cans pose a significant safety risk to the filling line which may result in machine standstills and even machine damage. The Cantronic sorts out all those "risky" cans thus increasing the overall line efficiency by approximately 5%.

Remote diagnostics and maintenance

The Krones Remote Service provides you with round-the-clock expert advice and support. If required, a Krones service engineer can access your inspector via a secure data link. Parameter settings, software updates and fault analyses can thus be carried out quickly, cost-effectively and with absolute security.

Protected access

Transponders protect the device from undesired access.

High degree of operational reliability

The Cantronic automatically rejects fallen-over containers and features a continuous self-monitoring function. Malfunctions and faulty operations are thereby prevented from the very beginning.

Uniform operating concept

All Krones machines are equipped with a uniform operating concept for maximum user friendliness.