Scalable, integrated and flexible analyses of your line

Quick reaction to quality problems

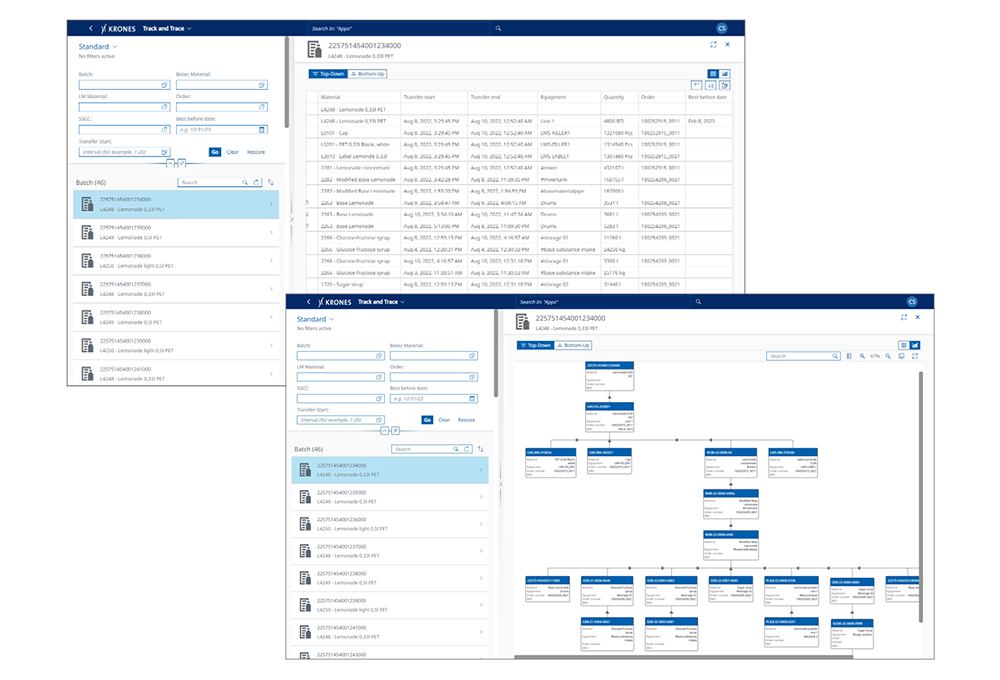

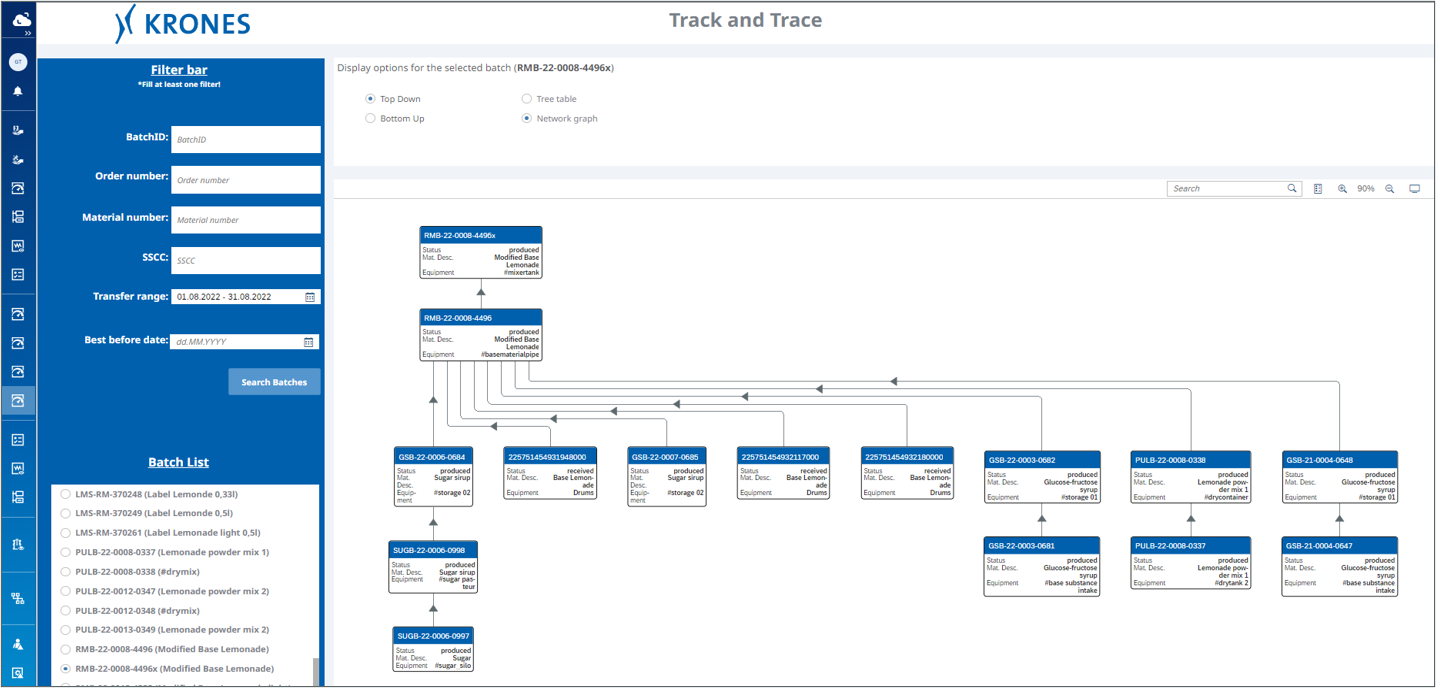

Regardless of whether you are dealing with the raw materials or the finished product –whenever quality problems arise, you mustbe able to react quickly. With Track and Trace Analytics, you can reliably section off suspicious products and raw materials so that they can be blocked or even recalled. The causes of quality problems are pinpointed quickly and reliably and you can make sound decisions based on convincing reports.

At a glance

- Search within a specific time period (tracking)

- Search based on product and material batches (tracking)

- Pallet search (tracing)

- Order search (tracing)

- Integration of external systems

Recognising batch and order-specific correlations

- Tracking of raw materials and batches, identification of consumption orders and production data

- Tracing of orders and production data, identification of consumed raw materials and batches

- In the case of recalls, the identification of batches due to deficiencies or defects

- Fulfilling of statutory requirements regarding the traceability of the components used

- Analysis of historical data

Requirement: Line Management and/or BOTEC must be installed as a data source.

Provides support in decisions at management level

Benefits to you

Cost-efficiency

Costs for blocked materials in the warehouse and recalls are reduced.

Time savings

Optimise your time-critical reports through the fast and comprehensive processing of all data.

Global availability

Use Track and Trace Analytics 24/7 –regardless of your location and selected end device.

Transparency

Track and Trace Analyticscollects all the relevant status changes and material movements.

Overview

The system translates a large amount ofcomplex information about your line into informative reports andthus makes it possible to use it as a basis for making sound decisions.