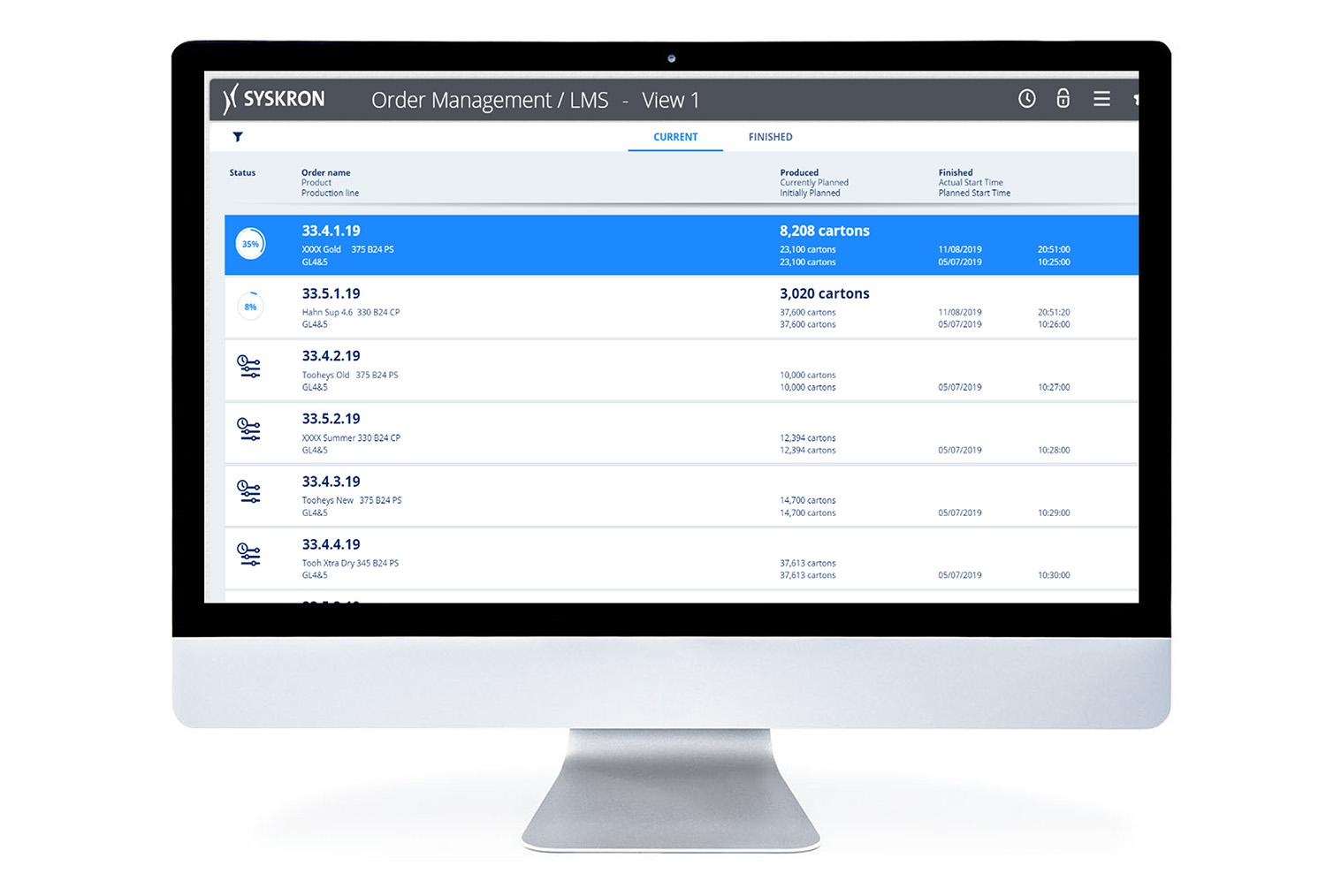

Co-ordinate the jobs and material in your filling line with ease

Line Management allows the entire filling and packaging process to be co-ordinated from a central position – from the definition of the

order-specific production route to pallet labelling.

Line Management provides a continuous flow of information, from production planning right through to the order for the line and

individual machine. To do so, the software considers your line to be a coherent system with production orders but not a row of isolated

individual machines.

At a glance

With Line Management you can

- optimally coordinate and process all orders in the filling and packaging area.

- reduce manual intervention, as the system takes over communicative and monitoring tasks.

- integrate label printers and coding devices into the line in order to automatically print important product information and best-by dates.

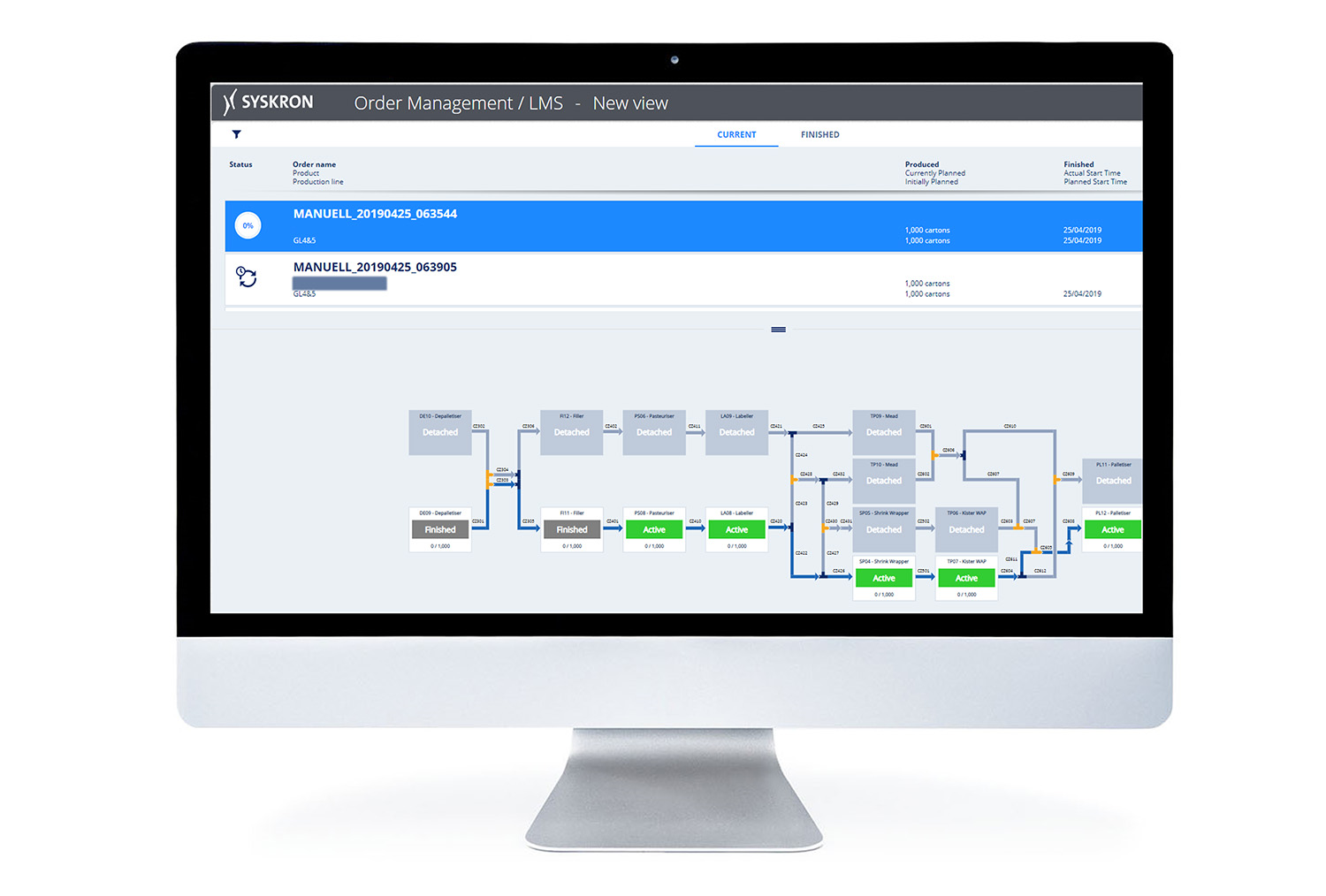

How Line Management works

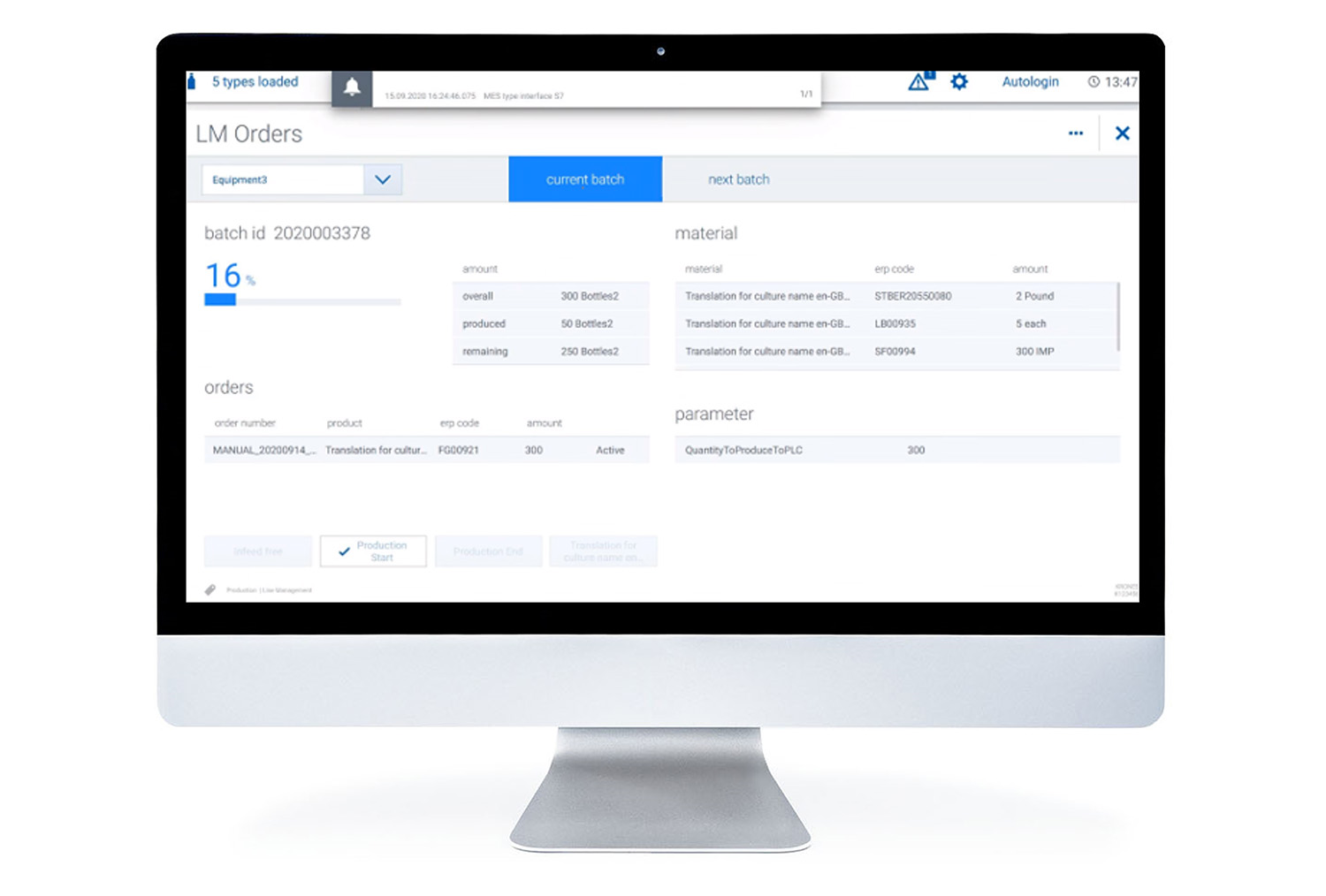

- Processing of individual orders with different batch sizes and

short reaction times - Online routing: Changes the route of the product within the

line while the order is already in progress - Ends orders based on efficiency (right down to the specific

tank/bottle or number of units) - Validates the materials used for optimum trackability

- Supplies all lines and machines involved in the order (including

printers and coding devices) with specific parameters - Standardised interface for the connection of any third party

machine - Organises highly flexible production lines, even over multiple

lines (for different products or routes)

Module overview

Providing support in all areas of production

Benefits to you

Saving production costs

You optimise your consumption of resources by requesting all processing and

operating materials always at the correct time.

Speed

The Line Management summarises several orders and you benefit from reduced

product change-over, conversion and cleaning times.

Quality assurance

Line Management helps to reduce your fault potential to a minimum and raise your quality and efficiency to a maximum level.

Line availability

You benefit from maximum capacity utilisation of your line through parallel order

processing, batch aggregation and order and batch changes on-the-fly.

User-friendliness

Line Management convinces due to its clear operator guidance and a reduced

manual workload.

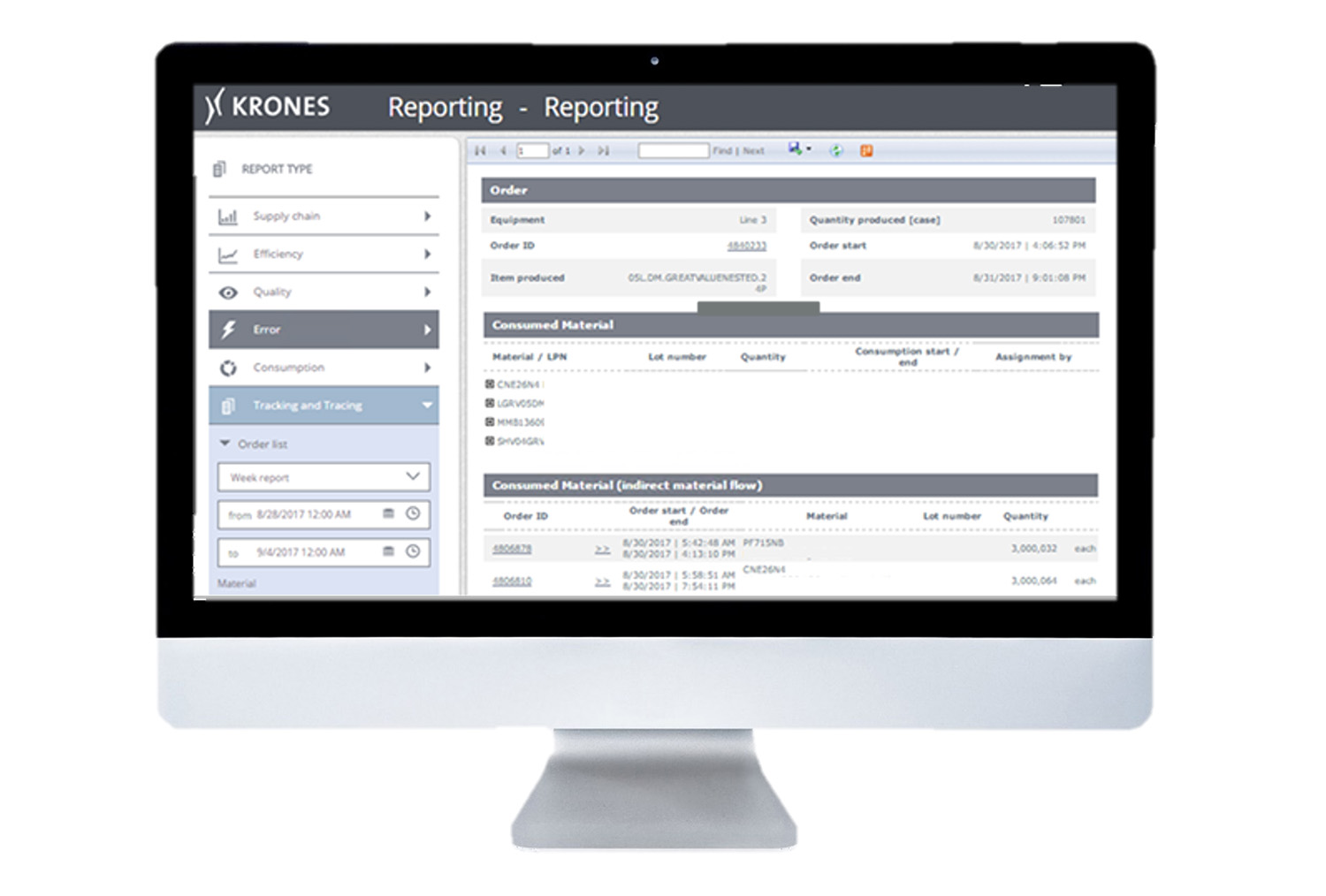

Product reliability

The software exactly records the production processes for each batch. You can exactly trace back each individual batch, even within quite complex product lines.