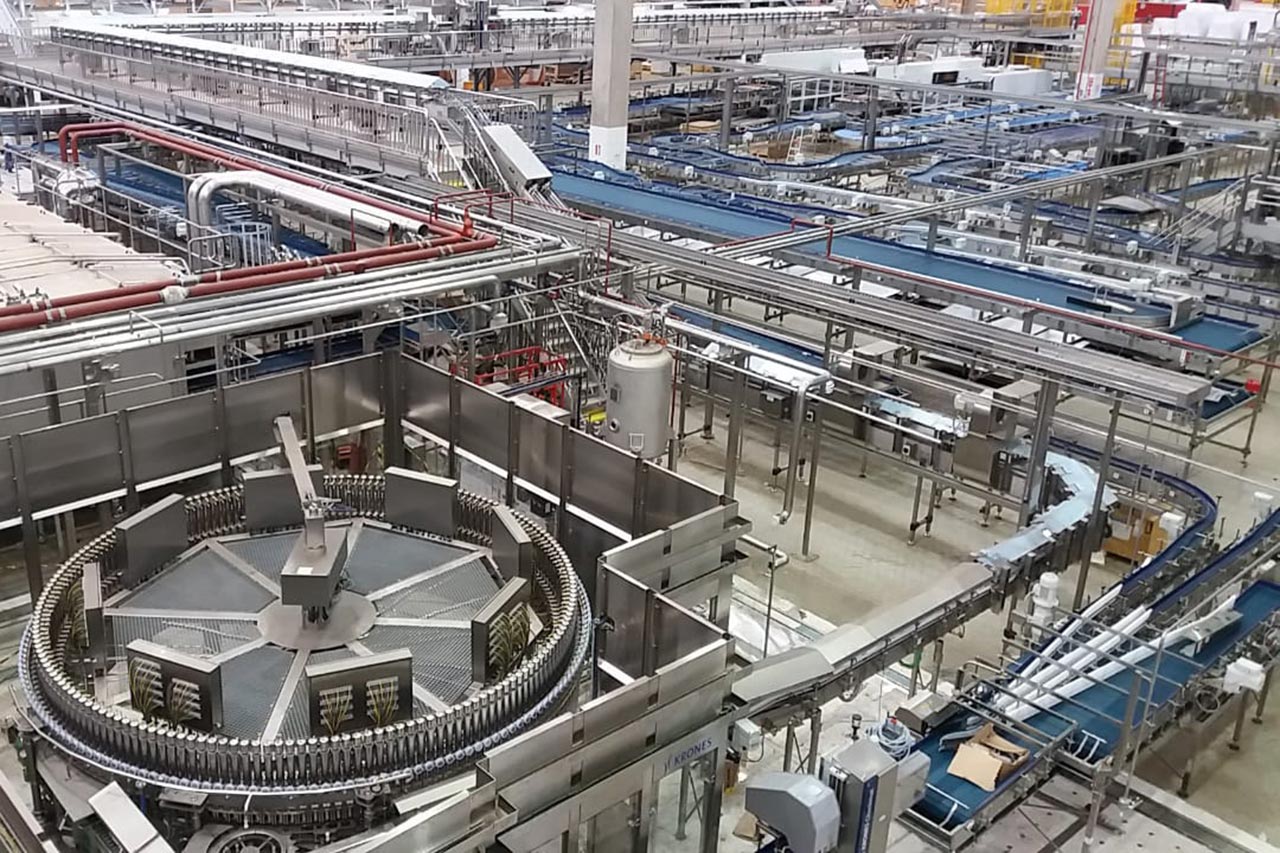

And if you’re thinking that the construction site must have gone pretty quiet, think again. There were still more than 150 people on site, including local employees from Krones and other installation subcontractors. While the German team assisted with the brewery remotely, our Brazilian service colleagues handled the entire installation and commissioning of the glass and canning lines – with the technicians in Germany standing by to help with questions as needed, of course. “We developed stringent hygiene policies in collaboration with Petrópolis for the work on site right at the start of the Covid-19 pandemic – it even covered hotels, restaurants, and the shuttle service between all of the locations involved,” explains Simone Roel Backes. “Masks and physical distancing were required, of course. Surfaces were disinfected twice a day, and any new visitors to the worksite were tested for the virus before entering.” The precautions and systematic adherence to those policies paid off: According to Simone Roel Backes, “Nobody in the entire construction site team was infected with Covid-19.”

In July, the pandemic situation in Brazil had improved to the extent that technicians were once again able to travel to the Petrópolis worksite from Germany. Gradually, around 60 percent of the original team returned. And that was not a moment too soon, because on 11 August it was time to start the first official brew! “The six weeks between their arrival and the first brew were intense – but they are also a testament to great teamwork,” says Simone Roel Backes. “Of course the project overall was delayed a bit because of the Covid situation. But the customer was very pleased that things nevertheless went as quickly and as well as they did.” Just two weeks later, the team gave the green light to begin filling on the canning lines – right on schedule. And then, the next highlight: The line achieved 95 percent efficiency, exceeding the level agreed in the contract. Both of the canning lines and one of the two glass lines have since passed their final acceptance tests. The second glass line went into operation in mid-February.